Univance group listens out for customers and promptly makes the best quality into shape in order to deliver products and services beyond customer expectations.

Univance has acquired skills, techniques, and experiences through our automotive manufacturing operations. To provide the best quality parts and services at all levels, we utilize ISO management tools and the Univance Production Way (UPW)

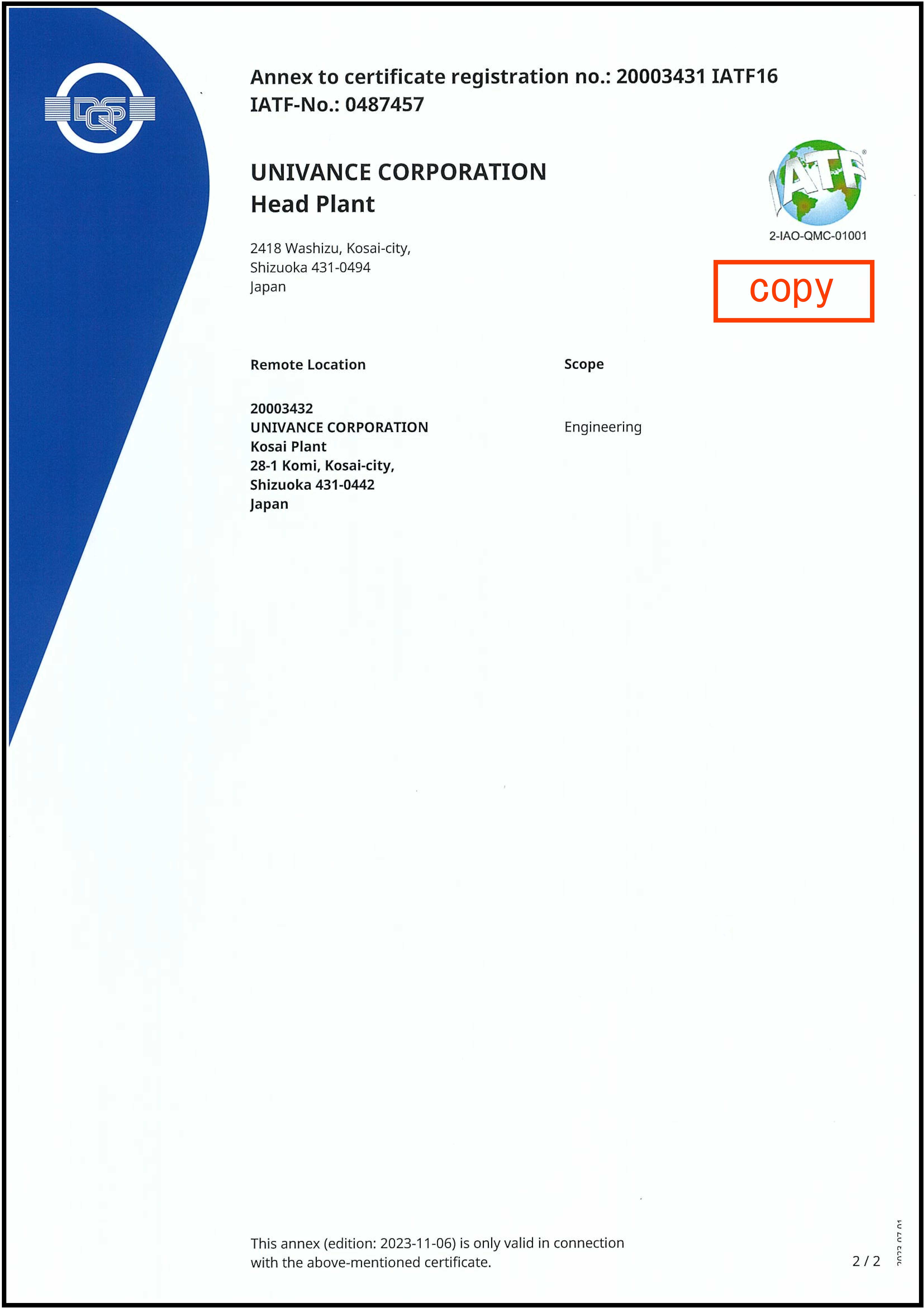

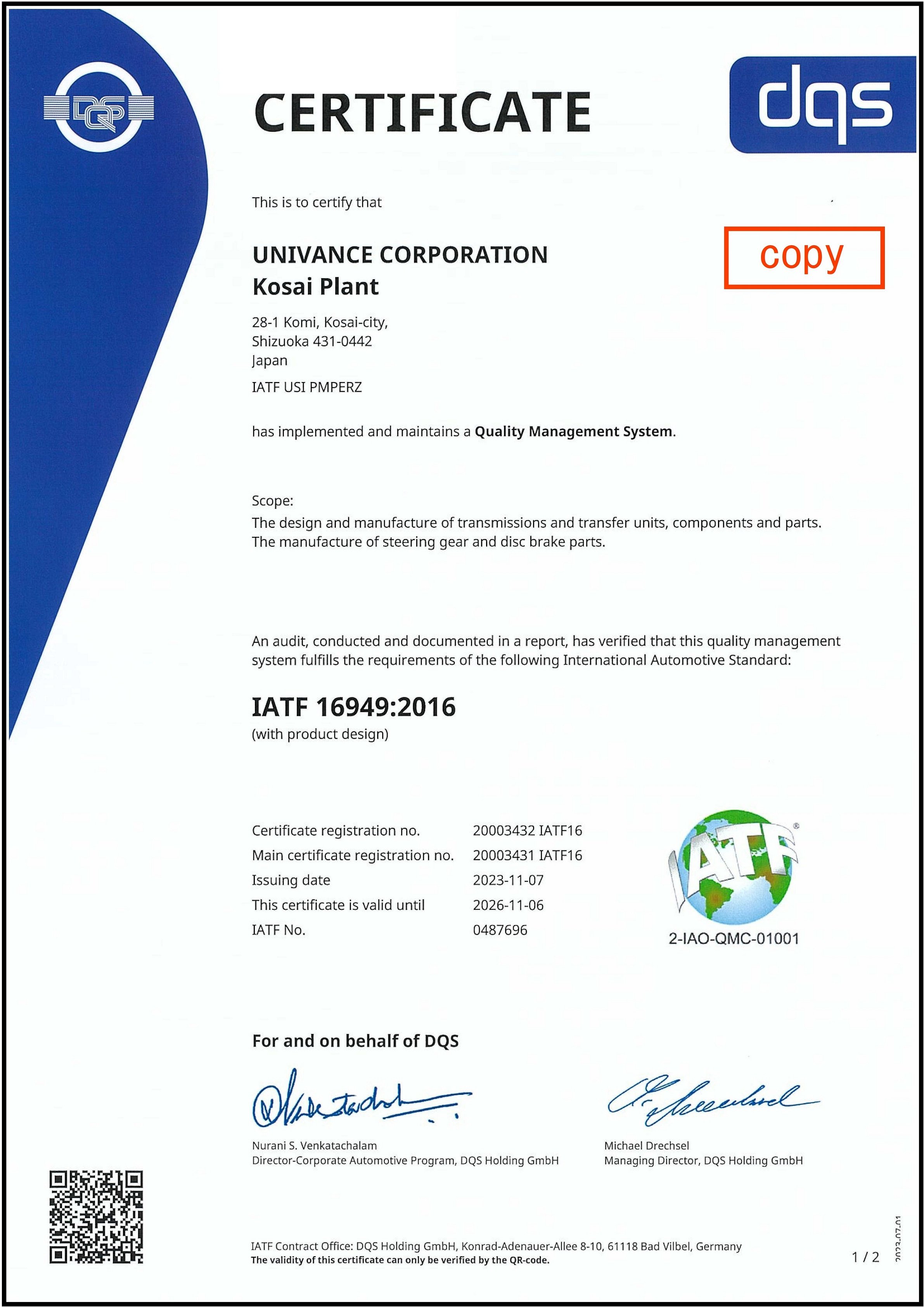

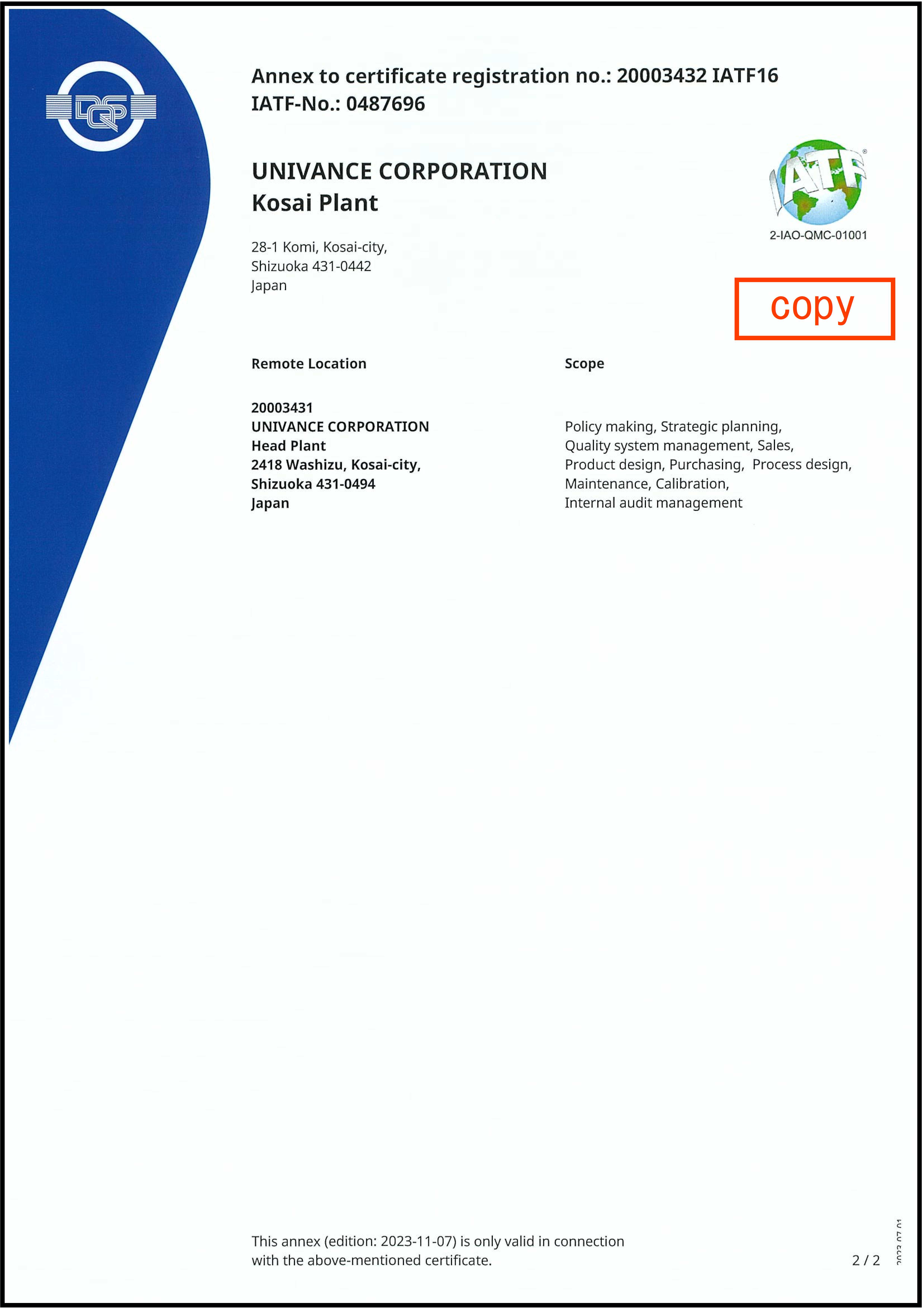

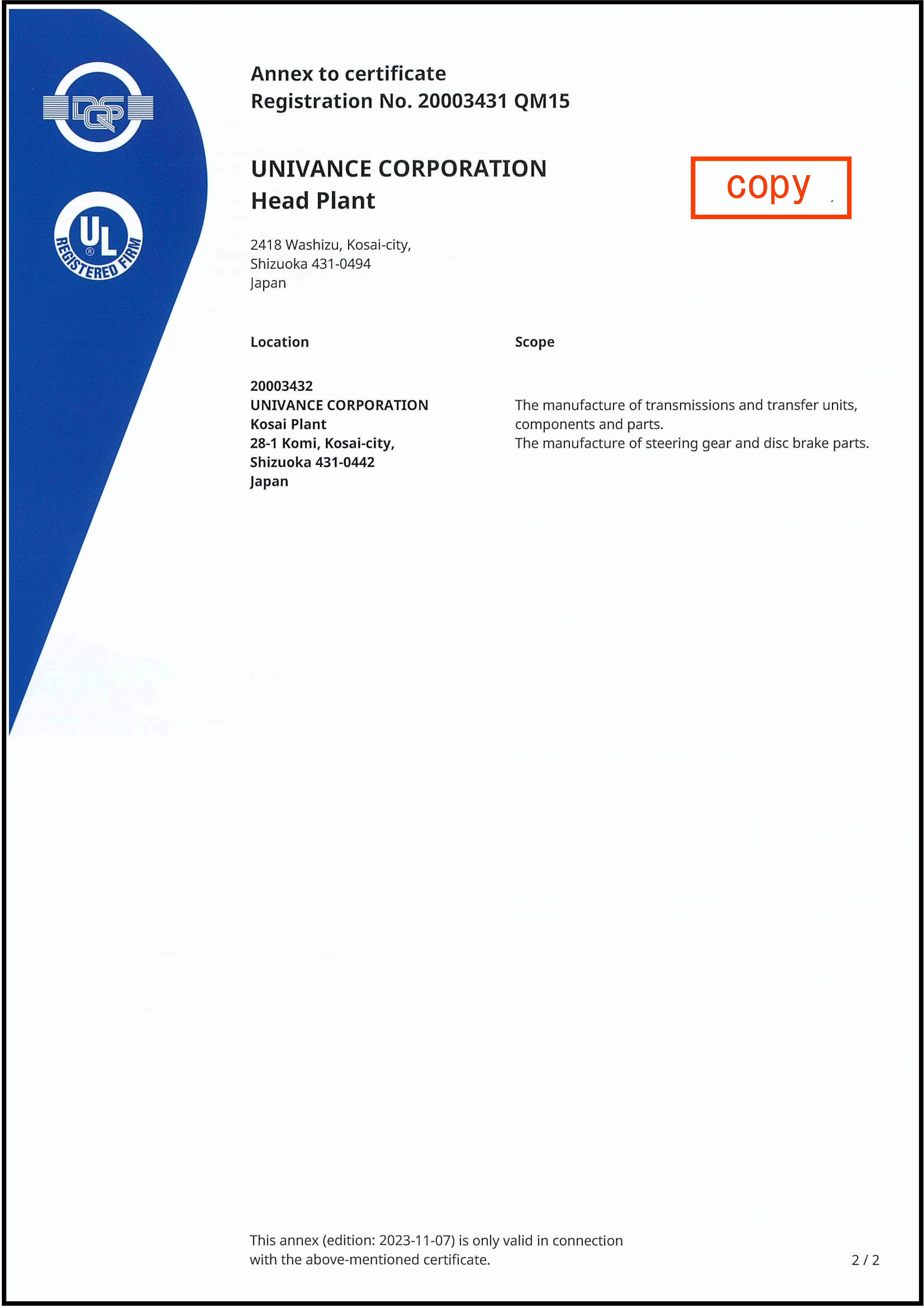

* ISO Management: Univance has obtained IATF 16949 certification for our domestic and overseas plants.

Our system allows us to share information inside and outside our group, quickly make appropriate decisions, and take action.

Since the founding of our company, we have invested in our people to cultivate individuals who can think and solve problems.

Since 1971, we have engaged in Quality Control (QC) circle activities for employees to practice what they have learned. Employees also take part in presentation forums outside the company, and in recent years our internal QC Circle presentation activities have expanded throughout the entire Univance group.

As technologies become more advanced and specialized, supply-chain quality assurance has become an important issue. In addition to conducting quality improvement activities, we recently started a new initiative to hold quality assurance meetings with our suppliers.

As a drivetrain specialist aiming to be the best in the world, we tailor our manufacturing activities by responding to the needs of each client individually. Our manufacturing incorporates artificial intelligence (AI) and the Internet of Things (IoT) to help us surpass our customers expectations for our parts and service.

download

download

more

more

more

more