My job is to improve production lines using the Univance Production Way (UPW). I work in the UPW Group who oversees kaizen activities meant to improve production lines' productivity and quality. Although our kaizen activities are mainly related to the Production department, we also have daily production activities that require us to collect data on bottle-neck processes in order to find problems and work together to create better production lines.

It is essential for us to collaborate with other departments to advance our kaizen activities, so I also coordinate schedules and set up meetings with the parties involved.

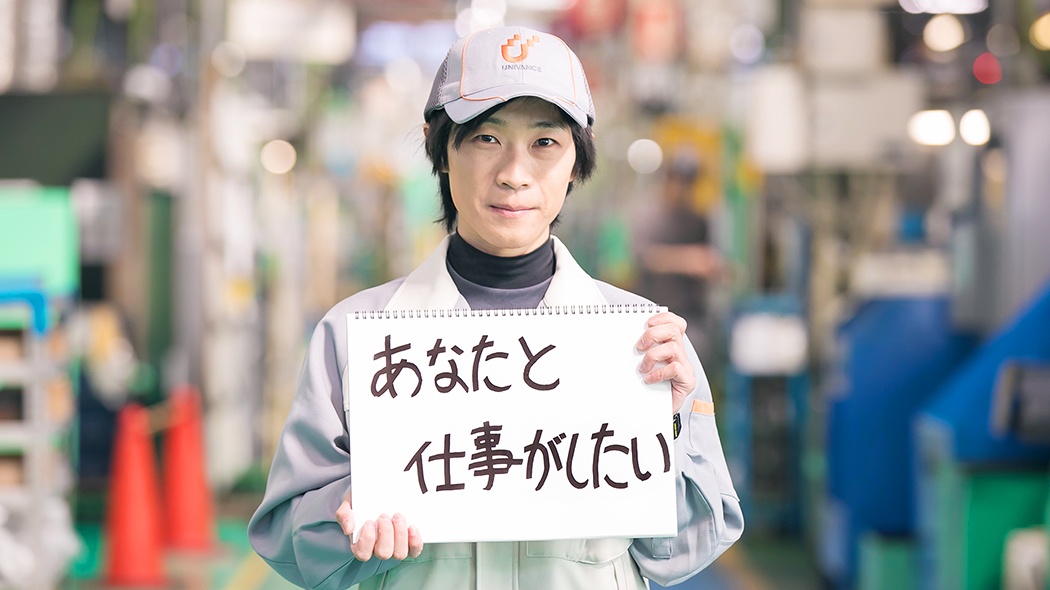

For my Kaizen activities to go forward, I need to persuade the Production department.

But I still don't have much experience and there are many things I don't know. My senior colleagues advised me to go to the production floor to learn, so I make a point of going out in the plant and talking to associates. I am grateful because I work with nice people who are always quick to teach me new things.

My work feels very rewarding when my Kaizen activities for the production lines go as planned and I can see the impact in the data.

Because I was studying engineering in school, I was looking for a company near my home where I can be involved in manufacturing. I decided to join Univance because of the technological skills it has as an independent manufacturer.

What I like about Univance is that my boss and senior colleagues are friendly.

Young people are treated as equals, and I feel like we can talk about anything. Another interesting thing about our company is that we several employees from across the globe. We have a lot of opportunities to travel to other countries, to listen to different languages, and to see many things with our own eyes.

Organize my tasks and determine what I can finish by when.

Film line startups to identify Kaizen opportunities

Conduct kaizen activities for new lines

Check the progress of lines participating in improvement activities, and review action items.

Clock production times on the production floor using stop watches.

Organize measurement data and prepare materials.

Have lunch with colleagues who joined Univance at the same time as me.

Check our department's progress versus this year’s targets and review action items.

Set the standard time needed to make a part.

I reflect on the day's events and leave by 17:15. I work overtime as needed.