I am responsible for process design. When I design a layout for a process, I select the most appropriate machining methods to manufacture products, determine production capacity, and consider a product's flow within our production facility.

I also coordinate the procurement of manufacturing equipment and accessories. I am currently designing a new type of assembly line which will be added to existing assembly line in our Thailand plant.

I have actually visited the Thailand plant to prepare for line modification and production.

I once made a jig to solve an issue that the Production staff encountered. Everyone in Production, from staff to managers and supervisors, said “thank you”and I felt good to be of help.

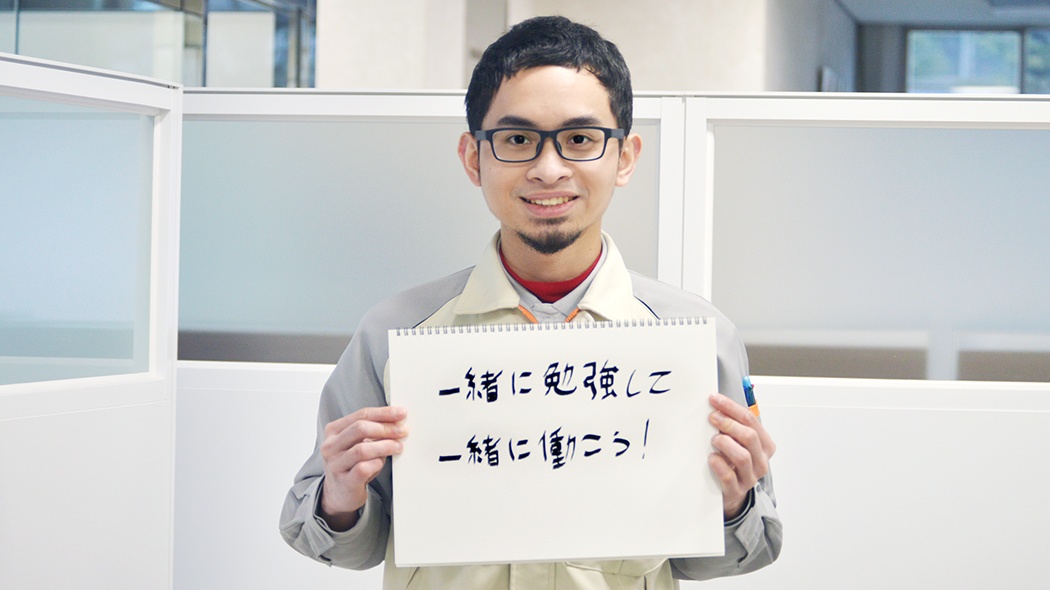

Once I joined the Engineering Planning Department, I experienced many things and gained a lot of knowledge. I am looking forward to more experiences and acquiring more technical knowledge. As a global company, I want to help Univance continue improving its technologies so it will be the best in the world.

Univance is one of the companies that was suggested by my university. I chose Univance because I get to work in my desired field, Engineering, and because I get to work with my long-time hobbies; cars and motorcycles.

Univance has a subsidiary in Indonesia, so the staff is used to communicating with people from Indonesia. My senior colleagues are kind and support me when I don't know the answer.

We have a morning meeting within our group and discuss reports and problems from the previous day.

Confirm equipment operations on the new line that we designed.

I check whether it's safe to work on a newly designed line. It's important to create lines that produce profit, but safety comes first.

We use a tool called FTA (Fault Tree Analysis) to analyze the root causes of machine breakdowns. We review all potential factors no matter how small they are.

An operation sheet is like a recipe for production, describing which parts, jigs, and tools to use and how to use them. When a model change forces us to change something, like a part or component, we have to revise our documents. This is a major responsibility because a mistake could have major impacts.

I work 1 - 2 hours of overtime and then go home. I spend time at home doing things like studying Japanese, and I sometimes go to a mosque in Hamamatsu.